What is the material structure of polyester film sand paper?

May 09, 2024

Polyester film sand paper is a widely used abrasive material in both industrial and craft applications. Its material structure plays a crucial role in its performance and effectiveness. The structural design of this material directly influences its properties and application results. The material structure of polyester film sandpaper is typically composed of several key components.

1. Polyester Film Base

The foundation of polyester film sand paper is a polyester film. This film generally exhibits high transparency and flexibility, capable of withstanding high tensile and compressive forces. Additionally, it possesses excellent chemical and water resistance, enabling it to maintain stable performance in various environments.

2. Abrasive Grains

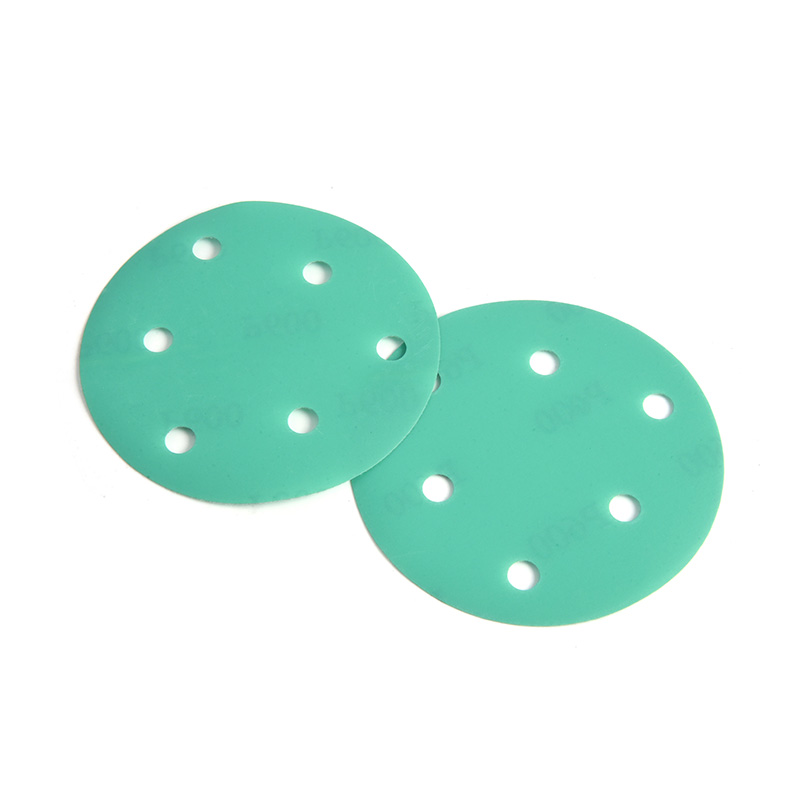

The surface of polyester film sand paper is coated with abrasive grains. These grains are commonly made from materials such as aluminum oxide and silicon carbide, and they come in different particle sizes and shapes to achieve varying degrees of coarseness. The uniform distribution and stable adhesion of the abrasive grains are crucial factors in ensuring consistent sanding results.

3. Adhesive Backing

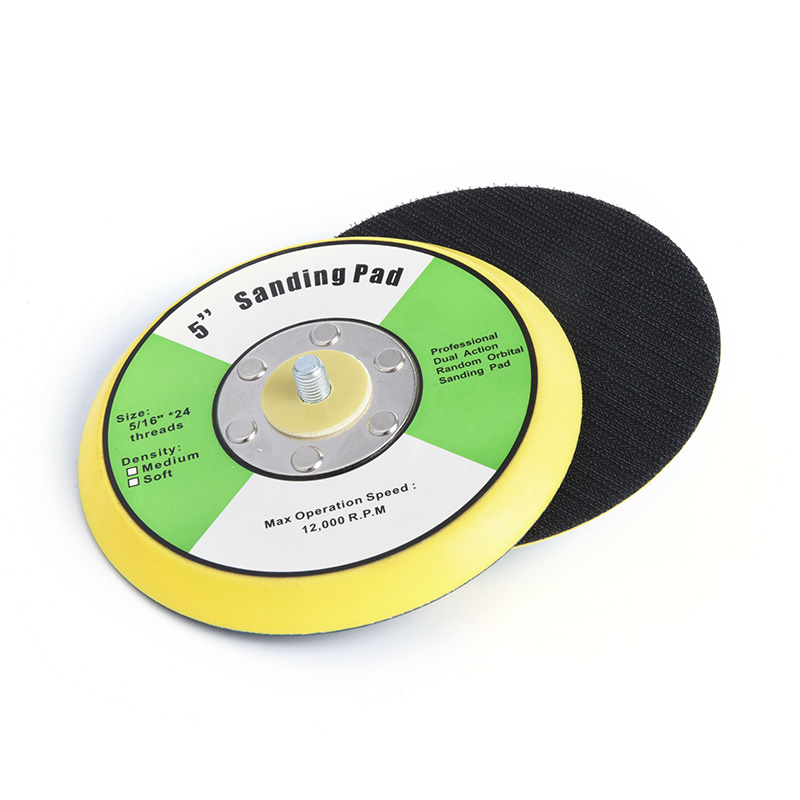

The backside of polyester film sand paper is often coated with an adhesive. This adhesive effectively bonds the sandpaper to the sanding tool or substrate, preventing loosening or detachment during the processing stage. Consequently, it enhances the stability and efficiency of the sanding process.

Material Structure and Properties

The material structure of polyester film sand paper, primarily composed of polyester film, abrasive grains, and adhesive, provides it with outstanding abrasion resistance, chemical resistance, and flexibility. This combination enables it to achieve efficient and precise sanding results, making it widely applicable in various processing and manufacturing industries.

Polyester film sandpaper finds extensive use in a diverse range of applications, including:

Surface Preparation: Preparing surfaces for painting, coating, or other finishing processes

Metalworking: Grinding and polishing metal surfaces to remove burrs, smooth out imperfections, and achieve desired finishes

Woodworking: Sanding wood surfaces to remove blemishes, refine textures, and prepare for staining or painting

Automotive: Sanding car bodies, components, and other automotive parts during the manufacturing and repair processes

Electronics: Polishing and finishing electronic components and circuit boards

Other Applications: Sanding plastics, composites, glass, and other materials in various industrial and craft settings

The versatility and effectiveness of polyester film sand paper make it an essential tool for a wide range of sanding and finishing tasks. Its unique material structure ensures consistent performance, durability, and adaptability to diverse applications.

English

English 中文简体

中文简体