How is the oil and water resistance of Polyester Film Sand Paper achieved through its manufacturing process?

Dec 06, 2024

Polyester Film Sand Paper chooses PET polyester film as the substrate. PET polyester film itself has a certain oil and water resistance, because the molecular structure of PET material is stable and not easily penetrated by grease and water molecules.

On the PET substrate, a layer of primer is attached by roller coating. This layer of primer not only acts as an adhesive, but also enhances the bonding force between the substrate and the abrasive. The formula of the primer is carefully designed to ensure that it has good oil and water resistance. The ingredients such as adhesive, filler, coupling agent and diluent contained in the primer are mixed in a specific proportion and can form a tough film that is not easily eroded by grease and water after curing.

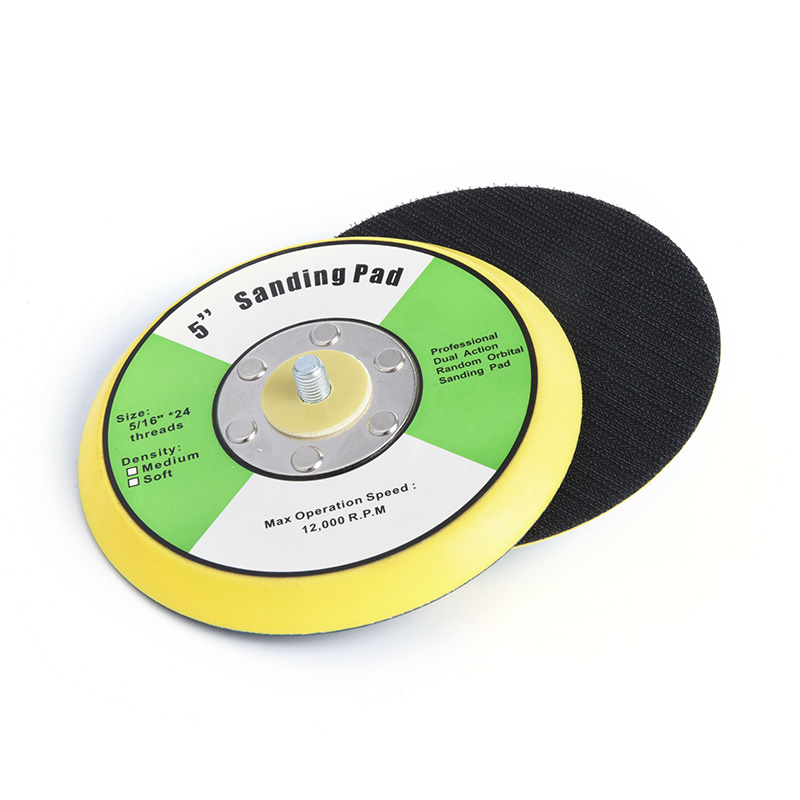

The abrasive is attached to the primer by gravity planting or electrostatic planting. Gravity planting is to pour the abrasive directly onto the substrate coated with primer, and use the abrasive's own weight and rolling to make it evenly distributed; while electrostatic planting uses the principle of static electricity to charge the abrasive particles and adsorb them on the substrate coated with primer. Regardless of the method used, the abrasive needs to be dried to ensure that it is firmly attached to the base glue. The drying temperature is usually controlled at 80~100℃ to prevent the base glue from overheating and becoming ineffective.

On the abrasive layer, a layer of top glue is applied by roller coating. The formula of the top glue is also carefully designed to enhance the oil and water resistance of the abrasive. The adhesive, filler, pigment and diluent contained in the top glue are mixed in a specific proportion to form a tougher film that is not easily eroded by grease and water after curing. After applying the top glue, the product is placed in a curing oven at 100120℃ for curing, and the curing time is usually 2448 hours. During the curing process, the adhesive in the top glue will react chemically to form a cross-linked structure, thereby further enhancing its oil and water resistance.

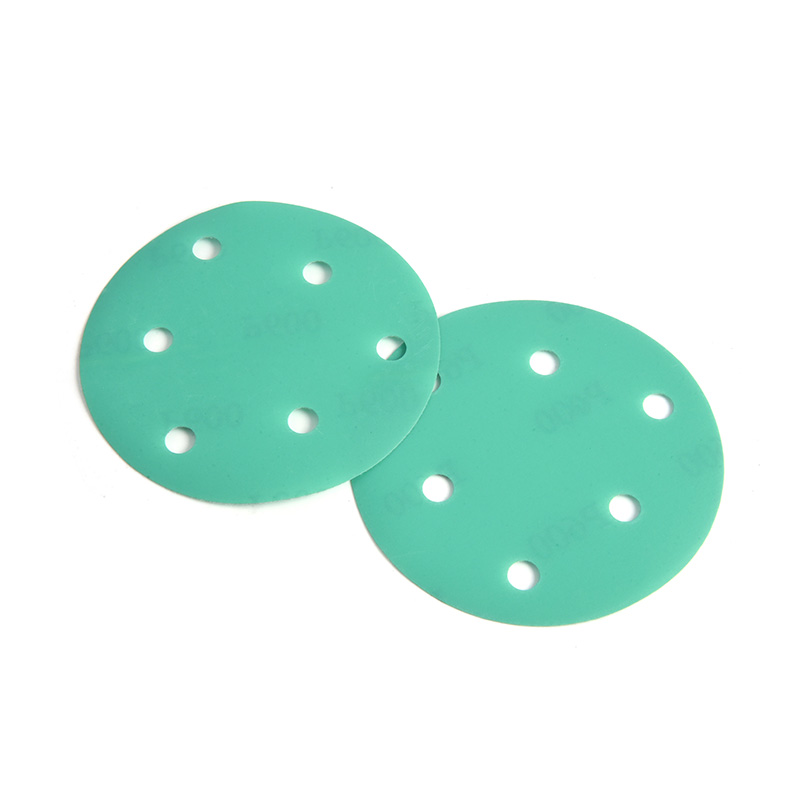

In order to further improve the oil and water resistance of Polyester Film Sand Paper, a layer of resin can also be applied to the surface of the sandpaper. This layer of resin can form a dense protective film after curing, which effectively blocks the penetration of grease and water. At the same time, the resin can also enhance the bonding force between the abrasive and the substrate, improving the overall durability of the sandpaper.

The oil and water resistance of Polyester Film Sand Paper is achieved through the manufacturing process of selecting an oil- and water-resistant PET substrate, coating an oil- and water-resistant primer and overcoat, and performing surface resin treatment. These measures together ensure that the Polyester Film Sand Paper can maintain good performance during use.

English

English 中文简体

中文简体