Can this foam polishing pad adapt to polishing surfaces of different hardness and roughness?

Sep 10, 2024

Foam polishing pads are made of foam material, which has the characteristic of gradually softening, so that the particles can be further released more evenly during the polishing process. This characteristic enables the foam polishing pad to adjust the polishing force according to the actual situation of the surface when dealing with surfaces of different hardness, so as to achieve better polishing effect.

The elasticity and softness of the foam polishing pad are the key to its adaptability to different surface conditions. This material can deform when subjected to pressure, but can quickly return to its original shape. This ability allows it to fit closely to surfaces of various shapes and roughness. Whether it is a smooth paint surface like a mirror or a rough and uneven metal surface, the foam polishing pad can adapt through its subtle elastic changes, ensuring that the pressure distribution during the polishing process is even, avoiding local over-polishing or omissions. In addition, this adaptability also helps to reduce scratches and wear during the polishing process and protect the integrity of the polished surface.

The reusability of HDO foam polishing pads is its significant advantage in terms of economy and environmental protection. Compared with disposable polishing products, foam polishing pads can maintain good performance after multiple uses and can continue to be used for new polishing tasks as long as they are properly cleaned and maintained. This feature not only reduces long-term costs, but also reduces the generation of waste, which is in line with the concept of sustainable development. In addition, the texture of the polishing pad may gradually become finer with the increase in the number of uses, and sometimes provide a softer effect for certain types of polishing tasks.

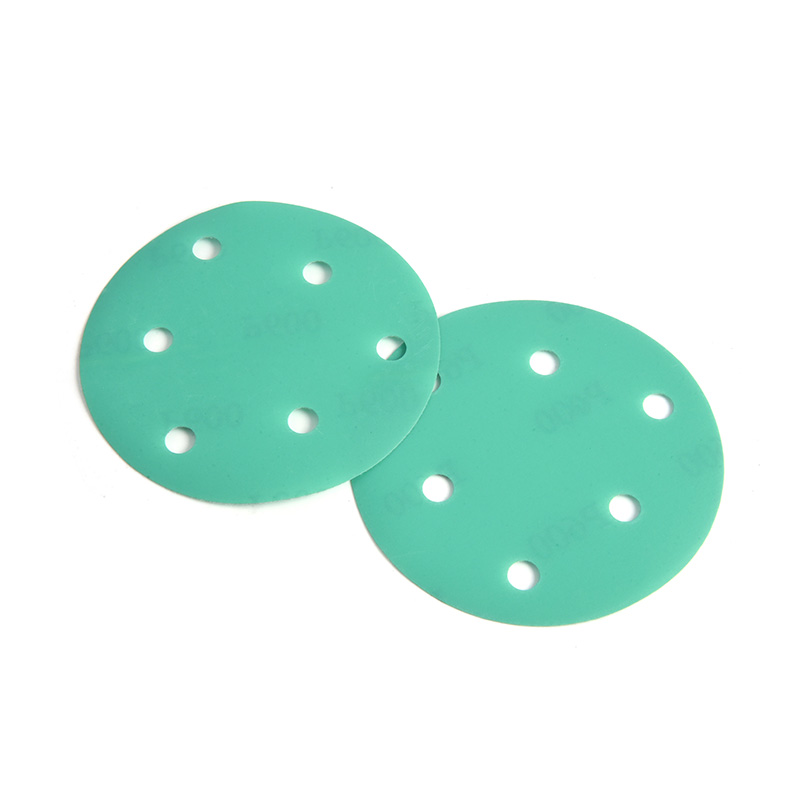

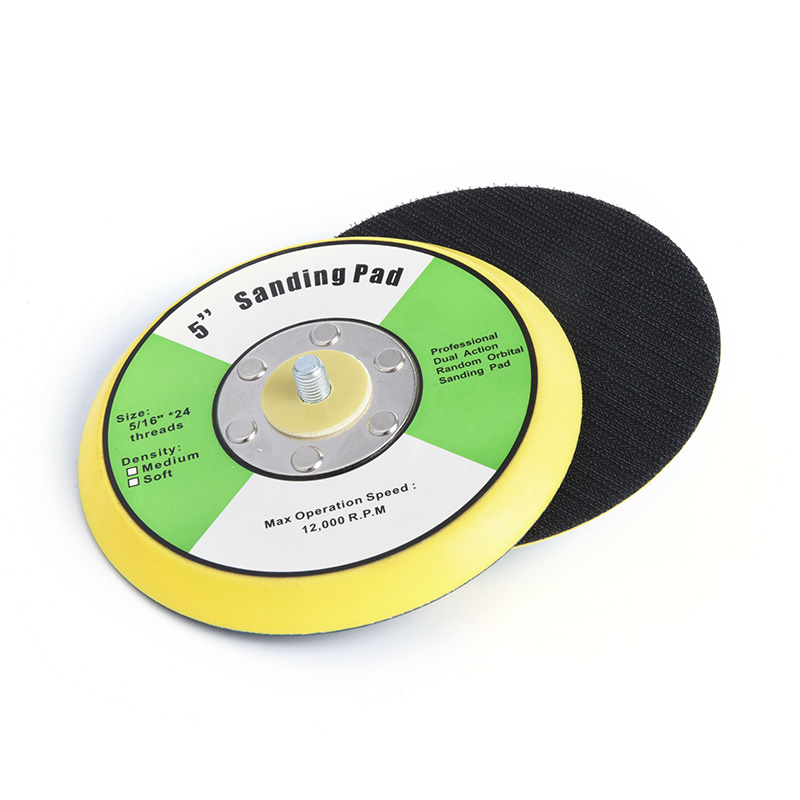

The flat bottom design of the HDO foam polishing pad facilitates its use in combination with sandpaper. This design allows the polishing pad to firmly fix the sandpaper to prevent sliding or falling off during the polishing process. By choosing sandpaper of different coarseness and fineness, users can easily pre-treat surfaces of different roughness and remove larger flaws and unevenness. On the basis of sandpaper polishing, fine polishing with a foam polishing pad can further eliminate fine scratches and flaws and improve the smoothness and brightness of the surface. This combined use method not only improves polishing efficiency, but also ensures the consistency and high quality of the polishing effect.

The abrasive and lubricant gradually released by the HDO foam polishing pad during the polishing process are the key to its excellent polishing effect. Under the combined action of heat energy and reaction force, these substances react chemically and physically wear the surface to be polished, thereby removing dirt, oxide layers and tiny flaws on the surface. At the same time, the effect of the lubricant reduces friction and heat accumulation during the polishing process, protecting the integrity of the polishing pad and the surface to be polished. This polishing effect is not only suitable for surfaces of various hardness and roughness, but also has a certain universality and can meet the polishing needs of different industries and fields. In addition, with the continuous advancement of technology and the continuous innovation of materials, the polishing effect of HDO foam polishing pads will continue to improve and improve. This foam polishing pad can better adapt to the polishing of surfaces of different hardness and roughness due to its material characteristics, elasticity and adaptability, reusability and the advantages of being used in combination with sandpaper.

English

English 中文简体

中文简体