Can foam polishing pads be reused?

May 09, 2024

Foam polishing pads are generally reusable. However, the number of times they can be reused and their lifespan are influenced by various factors, such as the material, quality, frequency of use, and usage conditions of the polishing pad.

Firstly, the material and quality of the foam polishing pad are crucial factors determining its lifespan. High-quality polishing pads typically exhibit better durability and stability, allowing them to endure more polishing cycles and prolonged usage.

Secondly, the frequency of use and usage conditions also impact the lifespan of foam polishing pads. If the polishing pad is frequently used or utilized on harder surfaces, its rate of wear and tear will accelerate, necessitating more frequent replacement. Additionally, excessive pressure or friction during use can cause damage and shorten the lifespan of the polishing pad.

Therefore, to extend the lifespan of foam polishing pads, the following points should be considered when using them:

Choose high-quality polishing pads to ensure that the material and quality meet the requirements.

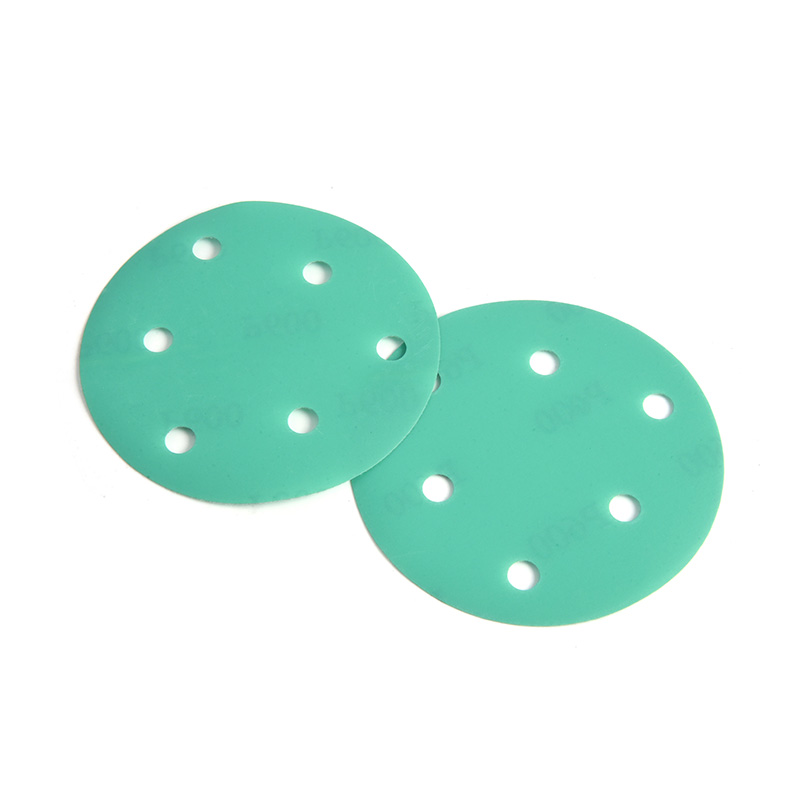

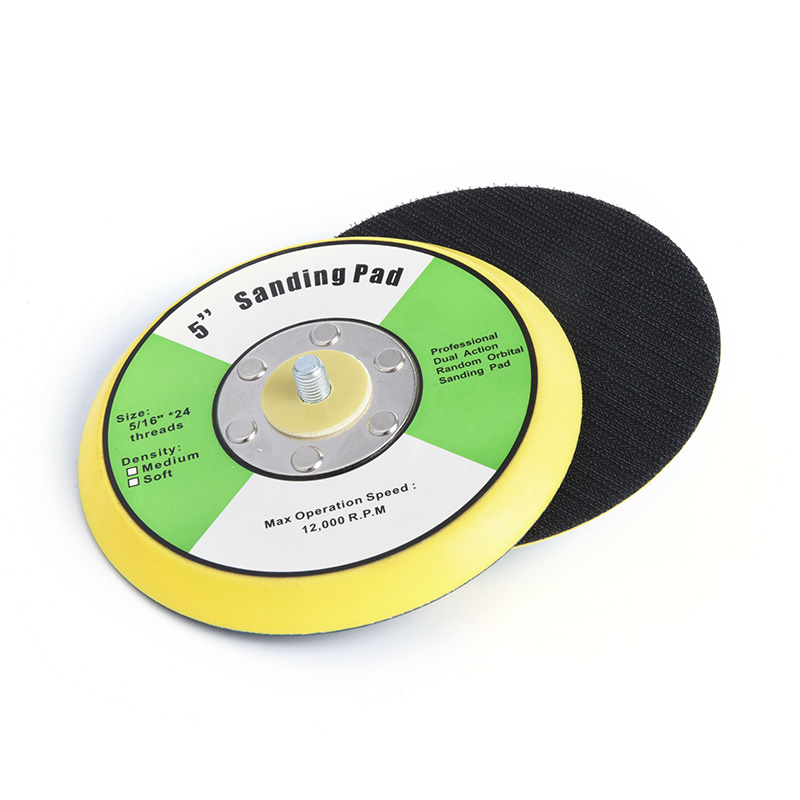

Select the appropriate type and specifications of polishing pads based on polishing needs and surface material.

Maintain appropriate pressure and speed during use to avoid excessive pressure or friction.

Regularly clean and maintain the polishing pad to keep it clean and tidy.

Replace the polishing pad promptly if it becomes damaged or its performance deteriorates.

In conclusion, foam polishing pads are generally reusable, but it is essential to choose the right polishing pad and use it correctly to extend its lifespan.

English

English 中文简体

中文简体